There are quite a few methods to enhance productivity and increase process efficiency. Some notable examples are 6-Sigma, Kaizen and Lean. Most of these methods are highly effective at identifying waste and redundancy, and pointing out where you need to cut, focus, or streamline. This leads very often to substantial savings and gains in efficiency. Unfortunately, as much as these methods excel at identifying where to save, they are seldom helpful in prescribing how to do so. When it comes to leading their users to ideate about potential alternatives or solutions to current wasteful practices, practically all productivity methods resort to… Brainstorming.

But, as research and practice has repeatedly and consistently established, Brainstorming is not an effective means for generating truly novel yet viable solutions.

.

In other posts [click here if you want to receive a copy] like “Busting the Brainstorming Myth” and “How Effective is DT as an Innovation Methodology?”, we have described some of the major faults of the BS method for ideation. Here, we will just briefly mention that BS tends to produce either unexciting ideas that are not new, or exciting ideas that are not viable. This is the point SIT – Systematic Inventive Thinking comes into play. As opposed to BrainStorming, SIT is a structured process calling for disciplined ideation within well-defined constraints. By changing the problem solver’s mindset, this process consistently leads to novel and effective approaches to problems and challenges.

Paradoxically, SIT requires that you focus on existing resources and capabilities (which is why the method is also referred to as “Innovating Inside the Box”), learning to use them in novel ways by breaking your so-called “Mental Fixednesses”. The method is therefore especially apt for constrained environments or systems defined by strict engineering requirements.

Here are some brief case studies that highlight how relatively small shifts in perspective, achieved through a structured process, can lead to substantially increased process efficiency.

HAVI – Opening a Bottleneck with No Additional Resources

HAVI is one of Asia Pacific’s largest logistics companies. At their depots in China, HAVI faced a consistent problem: delivery truck arrival times were frustratingly unpredictable, causing a slew of issues. For example, sometimes multiple trucks would arrive at the same time. And, since Havi had a limited number of truck unloaders, truck drivers spent unnecessary time waiting for their trucks to be unloaded. To avoid this process bottleneck, HAVI needed to find a way to streamline the unloading process.

HAVI considered various solutions, but none were cost-effective. They considered, for example, extending the warehouse to add docking space for extra trucks, but realized this renovation project would be prohibitively expensive and not necessarily tackle the workforce aspect of the problem. They also considered hiring a temporary workforce during busy periods. However, since the busy periods were often unpredictable, it would be impossible to foresee when the workers would be needed.

The Right Incentive

Using SIT’s thinking tool, Task Unification, which assigns a new and additional task to an existing resource, HAVI came up with a creative idea to improve their warehouse’s process efficiency: truck drivers arriving to the warehouse were offered the option of unloading the trucks themselves. Initially, this idea seemed totally untenable, as the drivers, it was believed, would certainly refuse to take on an additional and arduous task. But, after giving the option some thought, the Problem Solving Team realized that, given the right framework, the drivers would actually be more than happy to comply. With less downtime on the job, additional pay for the extra task, and more control over their schedule, the drivers had everything to gain.

By incentivizing drivers to unload the trucks and paying them for the time they spent unloading, HAVI utilized its existing workforce to solve its problem. Since drivers no longer needed to wait for unloaders, they could unload their trucks immediately, resulting in reduced time and quick turnover. By using SIT’s structured thinking process, HAVI managed to save time and money, while eliminating a problematic bottleneck.

Teva Pharmaceuticals – Doubling Production Capacity – Now!

Teva, an Israeli pharmaceutical company, experienced a surge in demand for a specific drug, to which we will refer here as Drug A, when a rival company went bankrupt and could no longer deliver it to market. As new clients approached Teva for Drug A, the company realized that they had an incredible opportunity to grow their business quickly. However, to do so, and ensure retained interest from the new clients, Teva had to double capacity in two weeks’ time. The issue, however, was that the manufacturing line for Drug A was already working at full capacity. While prior attempts to increase capacity had resulted in a 15% production increase, Teva needed a more drastic change.

Drug Cocktail?

In order to double production quickly without significantly changing their process, Teva turned to SIT and its systematic methodology. Using SIT’s Closed World Principle, which states that solutions to a problem can be generated focusing on existing resources, the Problem Solving Team collectively listed all the elements within the production line and its vicinity (the production line’s “Closed World”).

Through a mapping process, the Teva team first identified that the greatest challenge in dramatically increasing production with the current production line (let’s call it PL-A) was one of the stages of the process, Stage 7. At the same time, the team also came to an initially counter-intuitive concept: that they could consider as part of the Closed World, another, adjacent line: PL-B, in which a different drug was being produced.

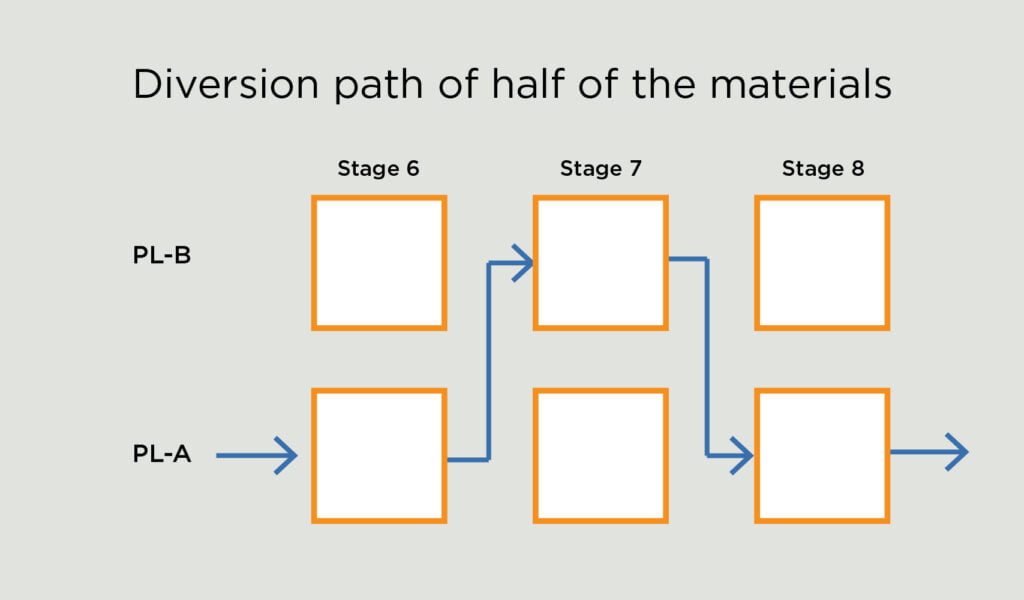

By analyzing each of these production lines and their processes, the Teva team arrived at a novel idea. It appeared that PL-B had a stage that was very similar to PL-A’s Stage 7 (the bottleneck). But, as opposed to the situation in PL-A, this stage in PL-B was actually working at only half its capacity! The ensuing solution was as simple as it was surprising: the team redesigned the PL-A process so that immediately after Stage 6, half of the ‘material’ on the Production Line was diverted to the neighboring PL-B, taking advantage of PL-B’s excess capacity in the relevant stage. After finishing Stage 7, the material was immediately rediverted back to PL-A to continue the regular Production Line A process to its conclusion (see diagram below). By using the adjacent Production Line’s (PL-B) capacity, Teva was able to double production with a minimal investment. This occurred almost immediately, giving Teva exactly what the company needed to match market demand for its drug.

Complement your Toolbox with a Counter-Intuitive Approach to Productivity and Process Efficiency

Most companies strive to improve process efficiency and enhance productivity. There is always some way to function faster, use fewer resources, or produce less waste. Traditional methods are effective in leading you to do so – but only to a certain extent. These methods usually point out where you need to act but fall short in helping you come up with novel ideas of how to do so. Using specific thinking tools and principles, SIT can do just that, helping you take full advantage of existing resources in surprising and innovative ways, ultimately leading to Productivity Through Innovation.